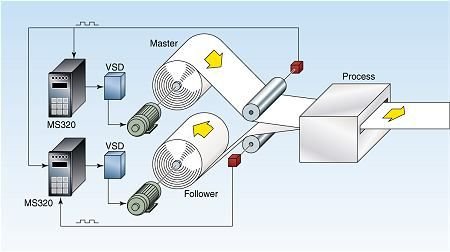

Many laminating processes require the coordination of two or more powered unwind stands thru an oven or adhesive process. In this example a MS320 is used in the master mode to set the line speed, i.e., FPM. The follower section is controlled by another MS320 typically set to run at a 1:1 ratio, enabling a smooth mating at the two materials. Both controllers will automatically increase the motor speed as the diameter of the rolls decreases to maintain the set line speed and ratio.