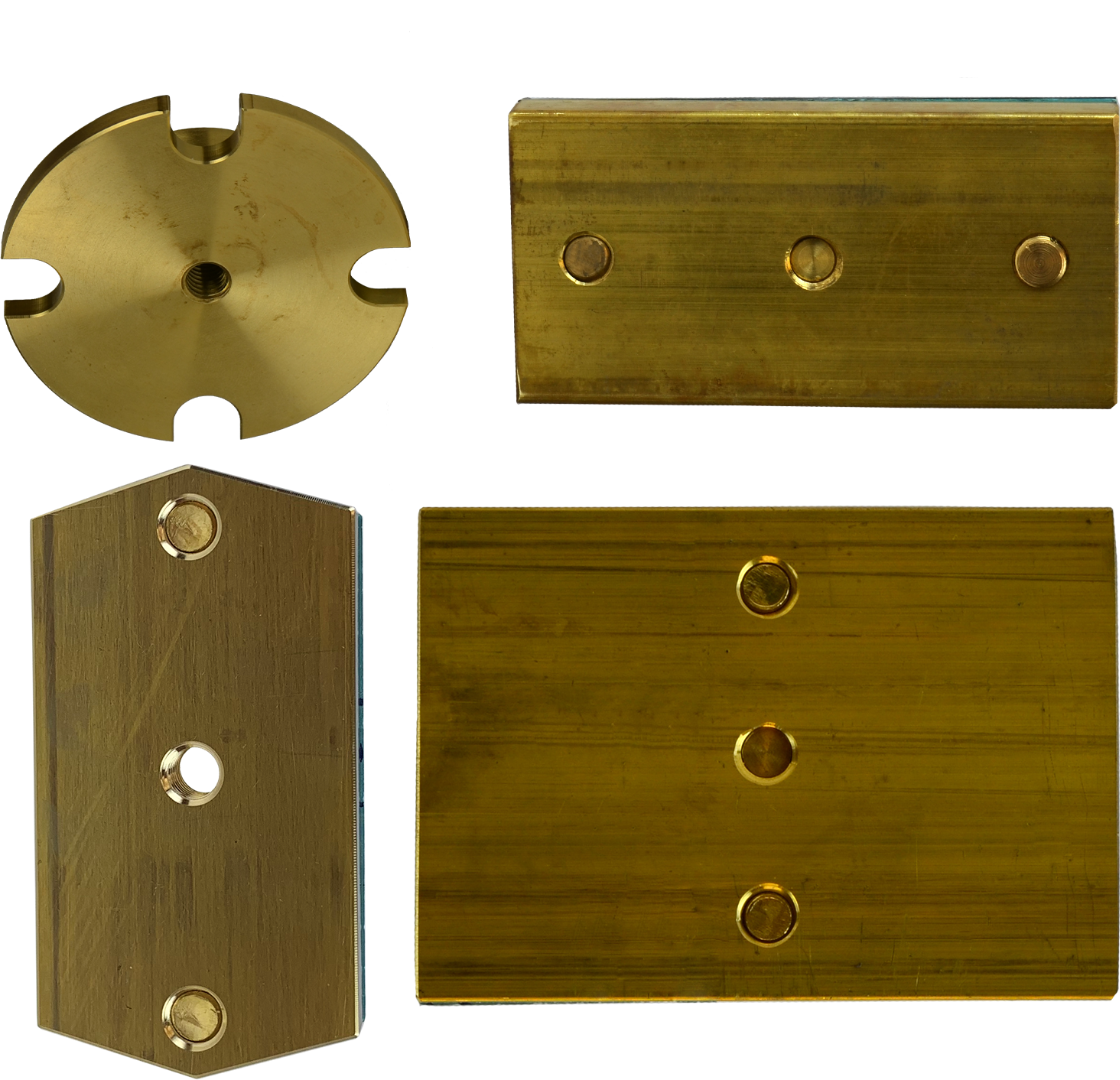

Brass Rub Block Options

Brass Rub Blocks are an essential tool for effectively maintaining the operational integrity of conveyor systems and bucket elevators. These Rub Blocks provide a vital early-warning system to detect potential belt misalignment issues, which are integral to ensuring the longevity and efficiency of material handling machinery.

Acting as heat sensors, Rub Blocks use the high thermal conductivity of brass to transfer frictional heat, generated by misalignment, to a temperature sensor. A noticeable increase in temperature detected by the sensor signals a potential issue with belt alignment. Electro-Sensors' Rub Block Door Assemblies add practicality to Rub Block installation and Inspection. The Brass Rub Blocks within these assemblies are independently replaceable, simplifying maintenance procedures and reducing downtime.

By providing accurate warnings of developing misalignment issues, Rub Blocks help prevent significant failures and enhance operational efficiency. Rub Blocks are a crucial investment for industries where continuous and reliable material handling is required.

Benefits:

- Keep Conveyors and Elevators Aligned

- Easily mount to Electro-Sensors Door Assemblies

- Monitors for rises in temperature due to belt friction

- Different model options to fit many applications

Rub Blocks are usually installed on each side of the belt in order to appropriatly monitor the belt for misalignment. Elevators commonly have 2 head, 2 knee, and 2 tail rub blocks. This allows for proper monitoring of the bucket elevator, on conveyors they can be installed in different quantities depending on the length of the conveyor.