-

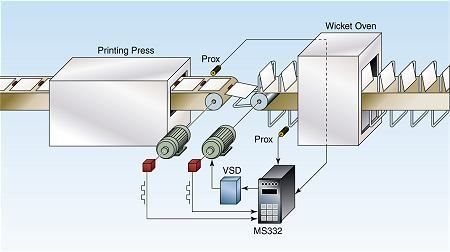

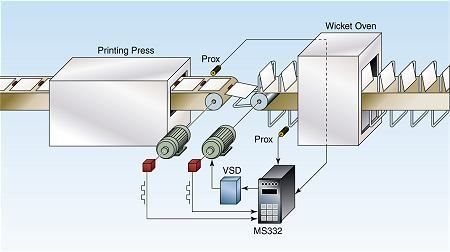

app_wicket.jpg

An illustration showing how MS332 units from electro-sensors manages a process between a printing press and a wicket oven.

-

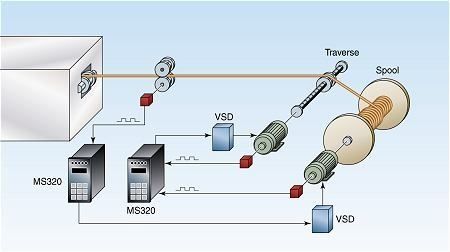

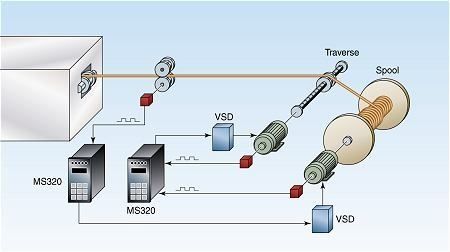

app_traverse.jpg

An illustration showing how multiple MS332 units from electro-sensors helps manage a cable winding process.

-

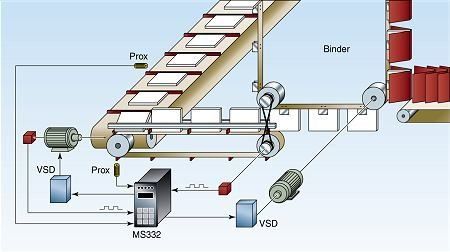

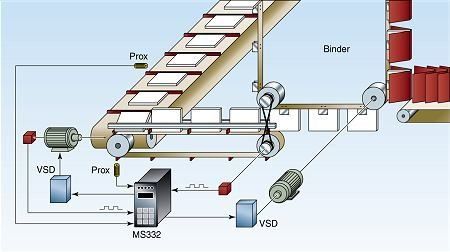

app_book.jpg

An illustration showing how MS332 units from electro-sensors help monitor the book making process.

-

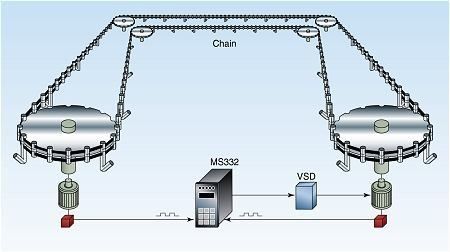

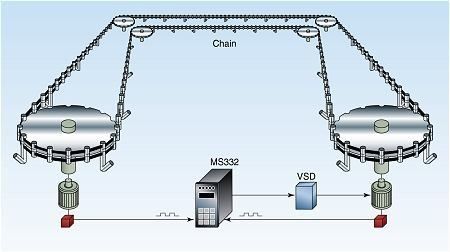

app_load.jpg

An illustration showing how MS332 units from electro-sensors monitors load on chain processes.

-

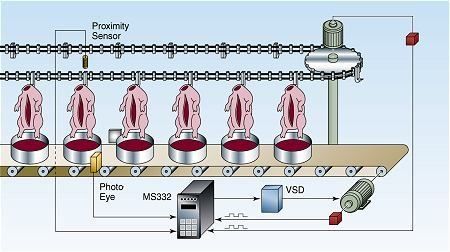

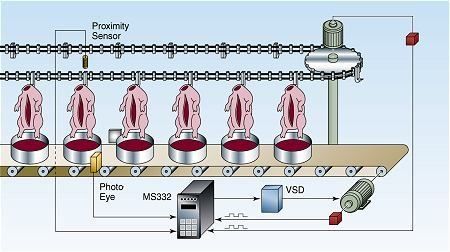

app_food.jpg

An illustration showing how MS332 units from electro-sensors help monitor the food processing process.

-

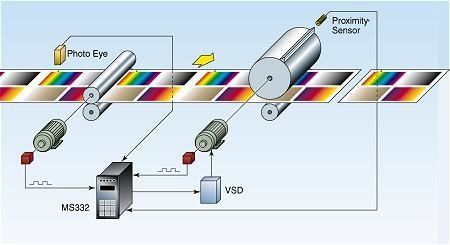

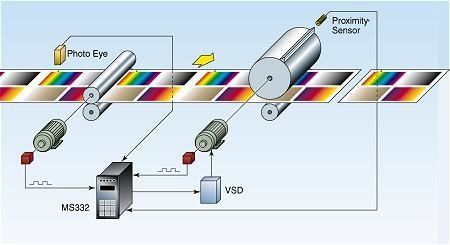

app_rotary.jpg

An illustration showing how MS332 units from electro-sensors helps cutting paper appropriately by monitoring inputs from a photo eye and proximity sensor.

-

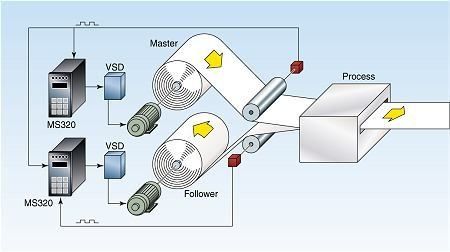

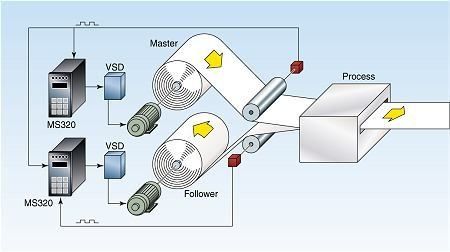

app_laminating.jpg

An illustration showing how multiple MS332 units from electro-sensors help monitor the laminated paper process.

-

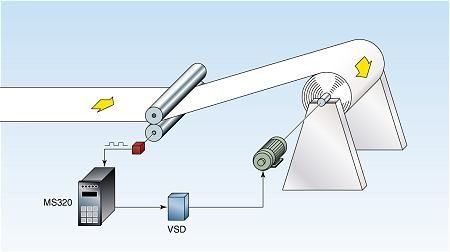

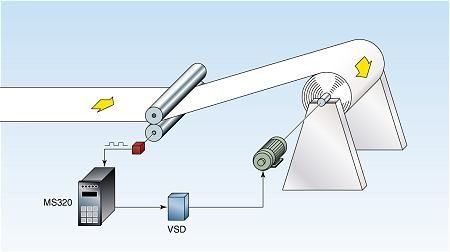

app_unwind.jpg

An illustration showing how MS332 units from electro-sensors manages a paper rolling process.

-

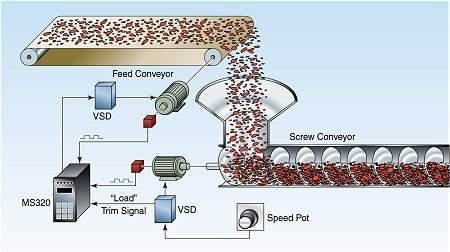

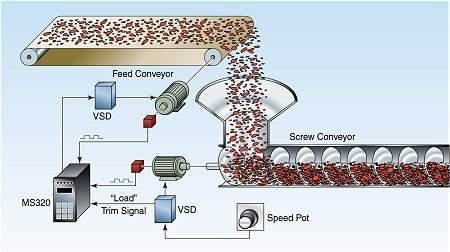

app_motor.jpg

An illustration showing how MS332 units from electro-sensors help monitor the motor load on a feed process.

-

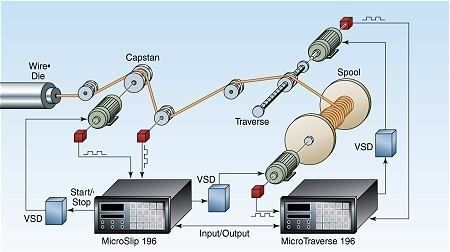

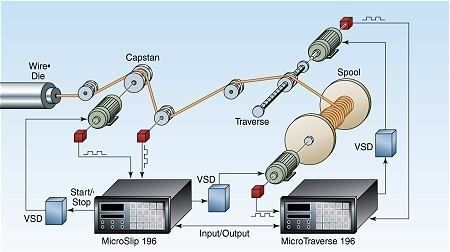

app_wire.jpg

An illustration showing how MS332 units from electro-sensors manages a wire spooling process.

-

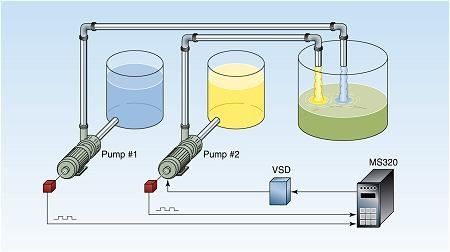

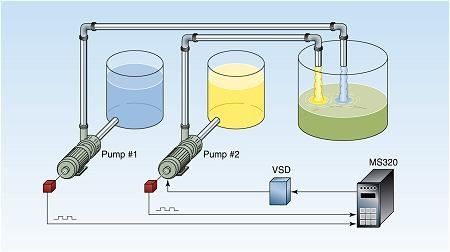

app_ratio.jpg

An illustration showing how MS332 units from electro-sensors help keep the proper mixture of liquids in the correct ratio for a final mixture.

-

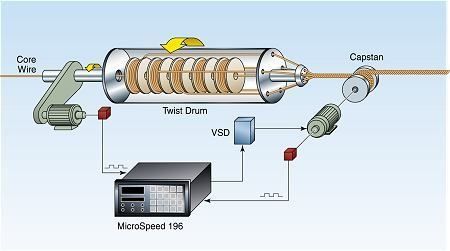

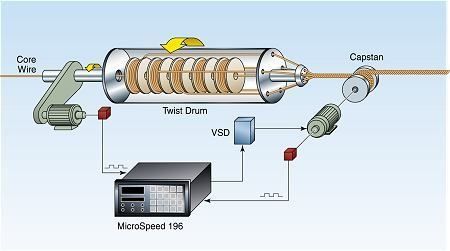

app_cable.jpg

An illustration showing how MS196 units from electro-sensors help monitor the Cable making process.

-

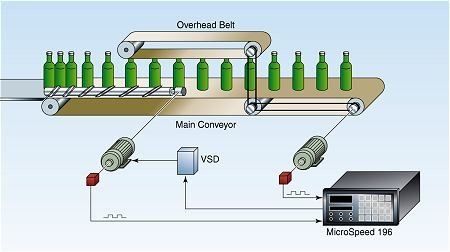

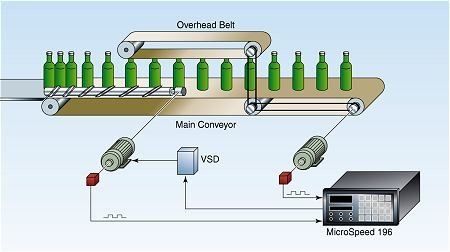

app_electronic.jpg

An illustration showing how MS196 units from electro-sensors help monitor the bottling process.

-

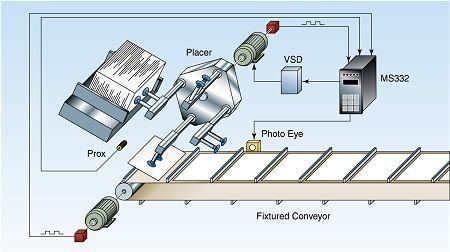

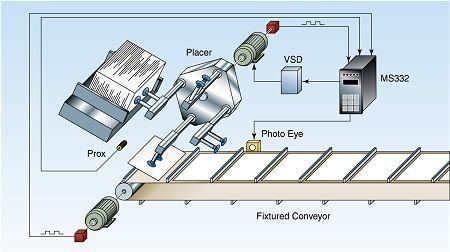

app_synchronized.jpg

An illustration showing how MS332 units from electro-sensors help synchronize a process utilizing a placer and photo eye.

-

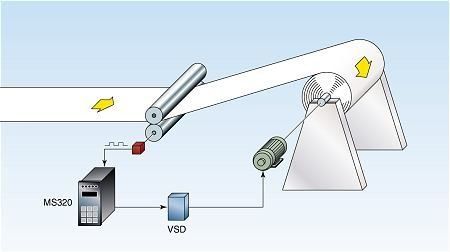

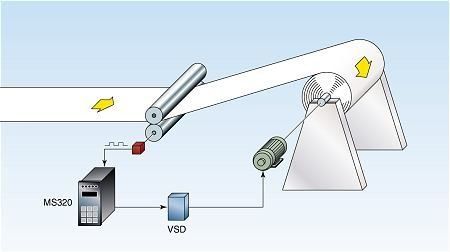

app_unwind.jpg

An illustration showing how MS332 units from electro-sensors manages a paper rolling process.

-

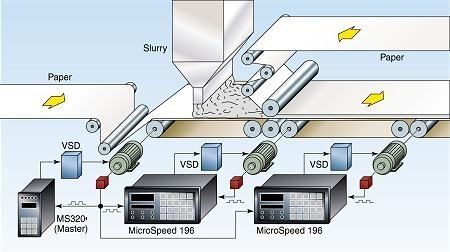

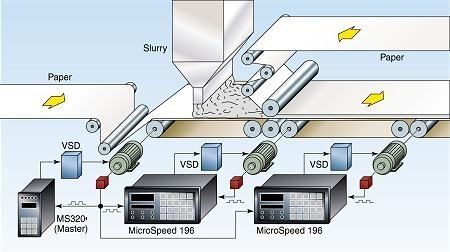

app_continuous.jpg

An illustration showing how MS196 units from electro-sensors help monitor the continuous paper/slurry making process.

Electro-Sensors provides only the motor controllers and feedback devices (ring kits or rotary shaft encoders) and is not responsible for the selection of motors and drive equipment. Electro-Sensors does not provide systems design, integration, or installation services. Contact your local systems integrator or electrical contractor for these services. Proper installation of our equipment is the sole responsibility of the purchaser and is in no way guaranteed by Electro-Sensors, Inc.