Machine Monitoring

What is machine monitoring?

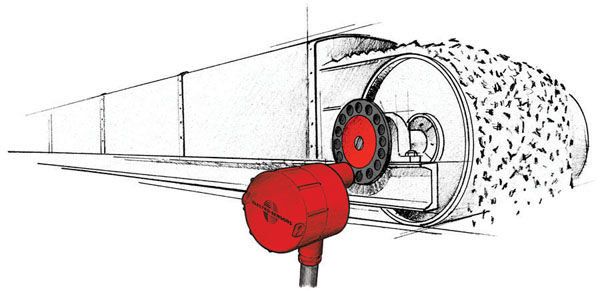

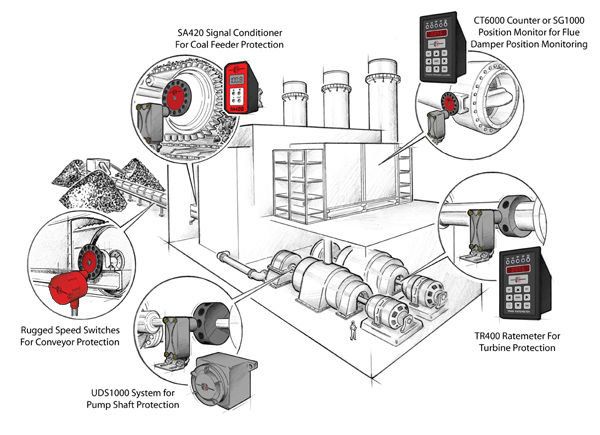

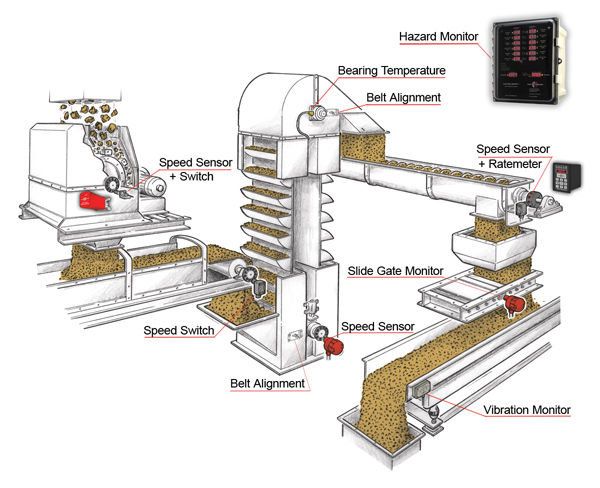

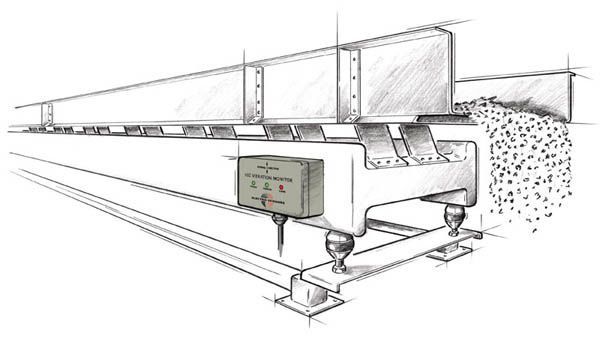

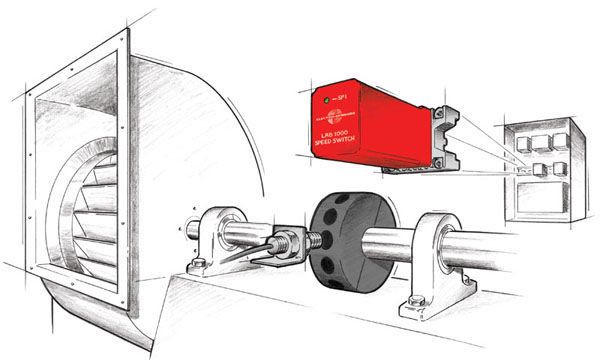

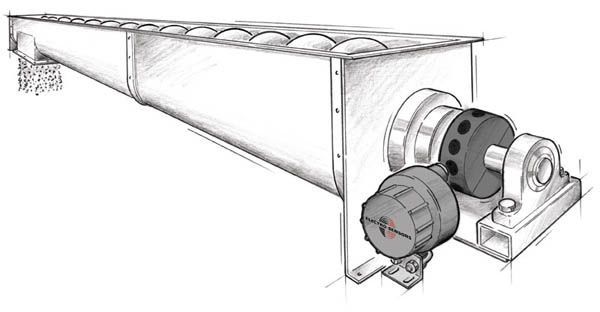

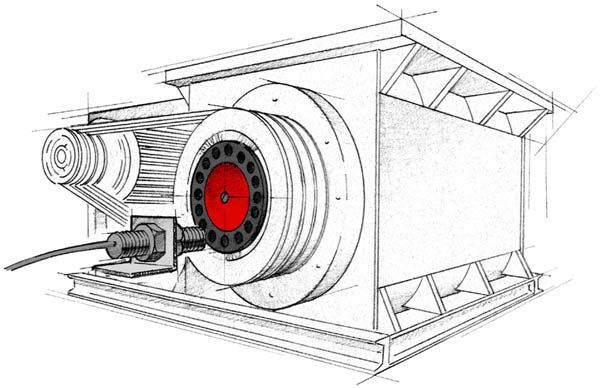

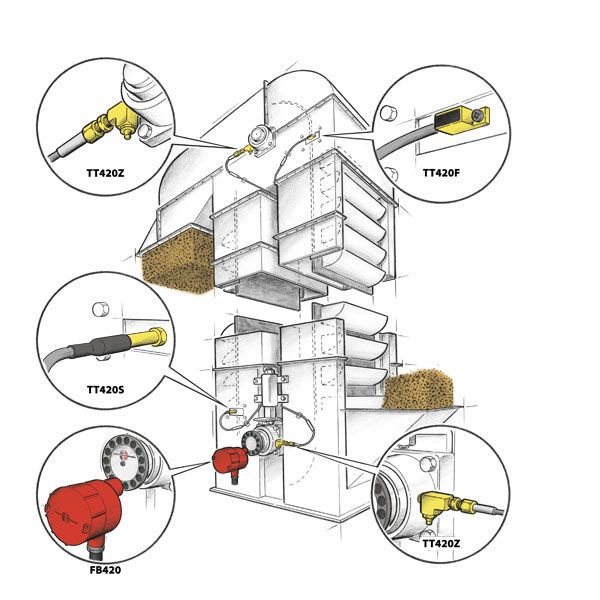

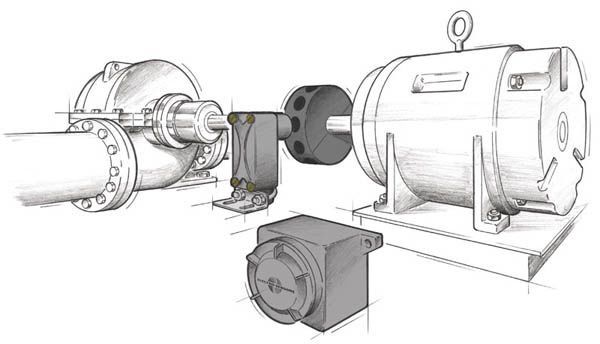

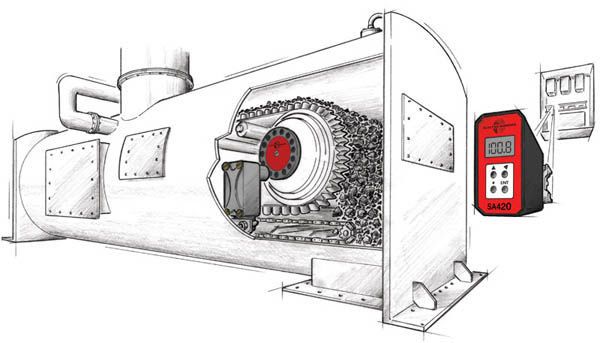

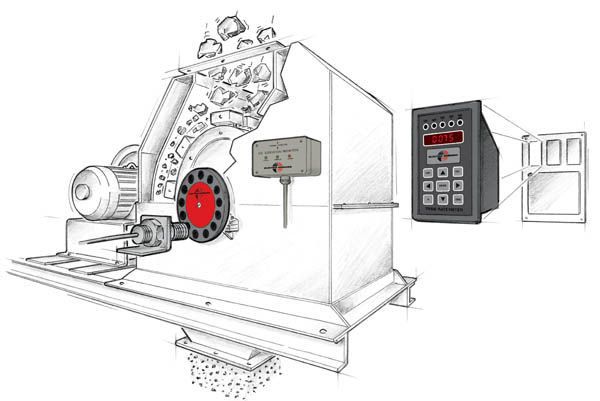

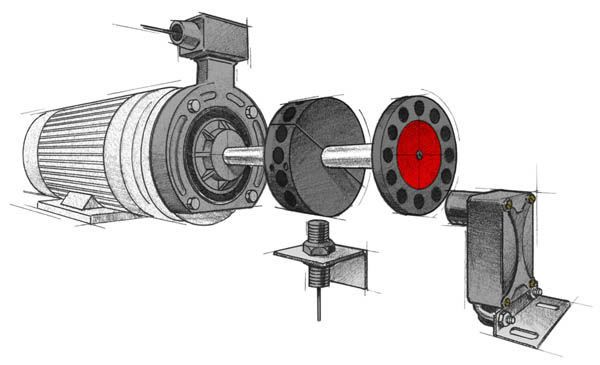

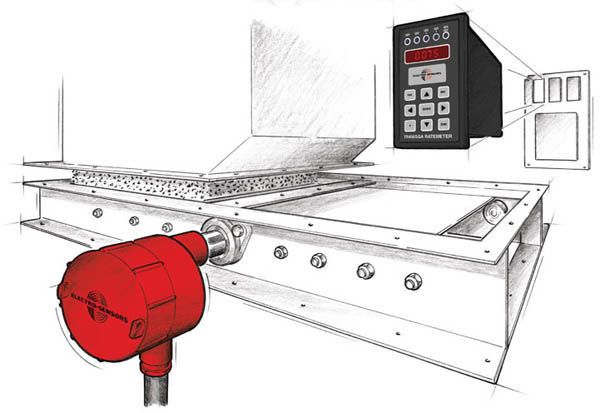

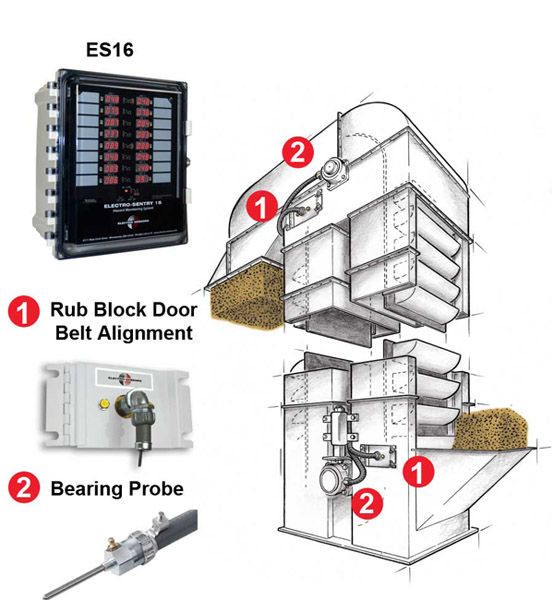

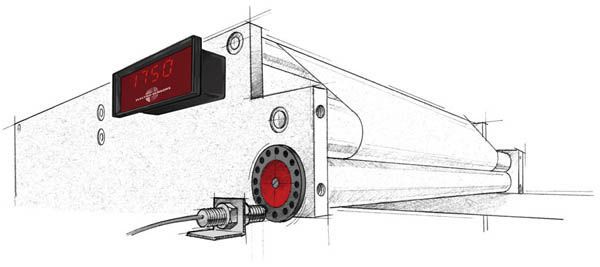

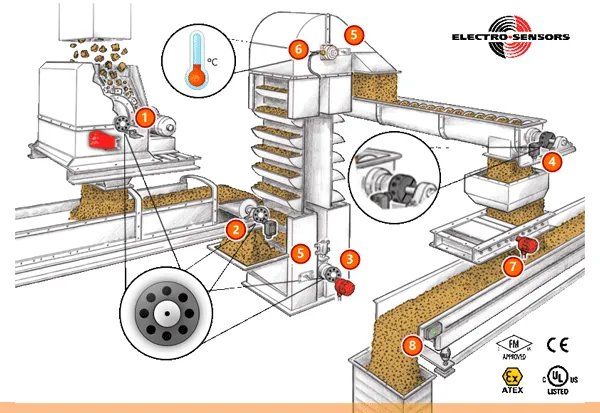

Machine monitoring involves using sensors to collect and analyze real-time data from equipment, enabling businesses to optimize machine performance, efficiency, and longevity. Our systems and sensors are leveraged across numerous industries, providing concise, accurate information on shaft speed, bearing temperature, belt alignment, slide gate positioning, vibration monitoring, and more.

Why do I need machine monitoring?

The return on investment for quality machine monitoring equipment cannot be overstated. By detecting potential failures before they occur, businesses can implement proactive maintenance, avoiding reactive responses that lead to significant downtime. Installing machine monitoring equipment is a straightforward investment that enhances machine health, lifespan, and efficiency. More importantly, it helps protect personnel and facilities from hazards associated with industrial machinery (read more about hazard monitoring here).

Which machine monitoring solution is right for me?

When considering which machine monitoring solution best suits your needs, make sure you’re looking for the essentials:

1. Ruggedness

In tough environments, whether explosive, corrosive, or flammable, we offer certified equipment for locations that need Class I, (A, B, C, D), Class II (E, F, G), Class III or NEMA certifications.

2. Simplicity

Our brand is marked by ease of installation and use, from the largest system down to the individual sensor. For example, the HazardPRO system manager touchscreen interface allows for effortless data visibility. On the smaller end, our speed-monitoring sensor heads are easy to position, requiring only a ruler.

3. Scalability

Electro-Sensors designs monitoring systems with scalability in mind. HazardPRO wireless hazard monitoring systems feature three unique system sizes. Small, Medium, and Large systems allow you to move from 240, 960, and 1920 sensors so that your system can match your needs without paying for unnecessary capabilities.

4. Quality

As a company that is dedicated to process improvement and safety, it is crucial that we adhere to the highest standards of quality. With this mission in mind, we are proud to be an ISO 9001:2015 certified company, which demonstrates our commitment to both customer satisfaction and best practices.

5. Service

Stellar technical support is the cornerstone of a well-running machine monitoring system. That’s why our team of knowledgeable experts is here to provide industry renowned service and answer any questions that you may have.

Our Machine Monitoring

For nearly 60 years, Electro-Sensors has been committed to providing customers with a standard of quality and integrity that leads the industry. When you choose our robust machine monitoring solutions, you are simultaneously enabling process efficiency, machine longevity, and workplace safety.

See our full line of machine monitoring options.

Below are many Machine Monitoring Applications for which we provide Industry Leading solutions. We are happy to help with applications that you don't see below, please contact our sales team and we will be happy to assist you and find the right solution for your application.